Geothermal Solutions

Optimize Geothermal Energy Production

Geothermal well completions require control, precision, and temperature-resistant tools. NCS Multistage is a world-leading manufacturer of reliable, controllable geothermal solutions that offer advantages to geothermal well operators in all phases of the energy extraction process.

Downhole tools and technology from NCS Multistage can be adapted to withstand the high temperatures common to most open-loop geothermal wells and offer an unprecedented level of control to operators because of the ability to open and close sleeves and adjust fluid injection rates.

NCS Multistage is currently supporting geothermal well operators and our comprehensive energy solutions have been applied in numerous geothermal wells across the globe. We enjoy partnering with customers to find solutions to problems and invite you to contact us about your next geothermal project.

One Source. Many Solutions.

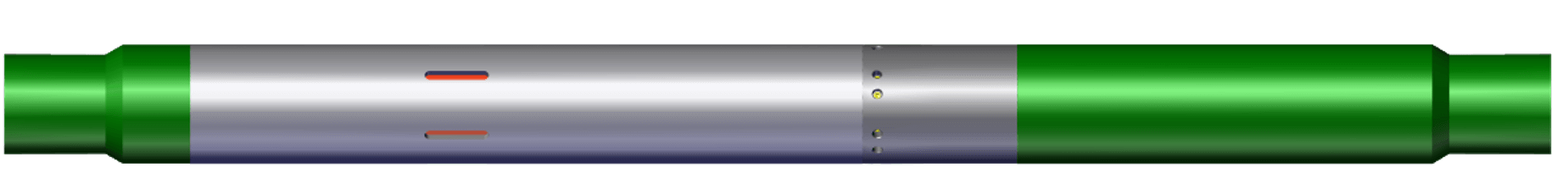

AirLock® Casing Buoyancy System

The AirLock® Casing Buoyancy System significantly reduces casing running time, cost, and risk without intervention or interference with casing and cementing operations. And geothermal wells have placed our record-setting tool in some of the harshest conditions yet.

The AirLock® Casing Buoyancy System has proven itself to be an invaluable downhole tool for geothermal well operators who need durable, temperature resistant tools backed by a team of professionals that can solve even the toughest geothermal wellbore challenges.

Features and Benefits:

- AirLock® operation is simple and passive, requires no intervention

- Section above the airlock sub filled with fluid, air filled section below sub remains buoyant

- Improved buoyancy allows deeper depth and reduces sliding friction by as much as 50%

- Sub contains high-strength dome-shaped pressure seal with shear ring

- More than 12,000 AirLock® systems installed with a success rate over 99%

Innovus™ HD Frac Sleeve

We understand the importance of control and functionality, that’s why we built a high-temperature sleeve that provides optionality through every phase of energy extraction.

Innovus™ HD frac sleeves are used for stimulations that involve higher frac rates, concentrations of sand, and total tonnage and are compatible with Innovus™ frac-isolation assemblies that have special erosion-resistant components positioned across the frac ports.

Additionally, Innovus™ HD frac sleeves incorporate premium MBED™ reclosing seals and other features that ensure reliable performance in the most demanding applications.

Features and Benefits:

- Can be deployed in cemented or open hole

- Operated by the Innovus™ frac-isolation assembly

- Deployed on coiled tubing or jointed pipe

- No pumpdown plugs or balls required

- No drillouts needed

- Accommodates frac rates up to 80 bbl/min (12.7 m3/min)

- Sleeve make-up length is 40 in (101.6 cm) or less

- Allows frac-port spacing as close as 15 ft (4.6 m)

- Compact and easy to handle

- No pup joints required for API connections

- Sleeves can be torqued through

- Sleeves can be installed in any order

- Proven functionality for stage-by-stage management

- Optional Shift-Frac-Close® sequence stops proppant flowback

- Allows fracs to heal before reopening sleeves for production

Innovus™ Convertible Frac Sleeve

The Innovus™ Convertible Frac Sleeve features a dual inner barrel and can be converted post-frac or post-production for regulated water-injection using the Torius™ regulator.

This enhanced functionality allows geothermal well operators to optimize geothermal heat extration from injector / producer well pairs by regulating and optimizing flow. This helps to avoid “cold circuits” and inject evenly between injector and producer wells.

Additionally, the ability to open and close all stages at once allows for simplified remediation operations and to assess individual frac stages for flow performance.

Features and Benefits:

- Special-purpose sleeve with a dual inner barrel

- Can be deployed in cemented or open hole applications

- Injection regulated by a calibrated tortuous flow path

- Deployed on coiled tubing or jointed pipe

- No pumpdown plugs or balls required

- No drillouts needed

- Supports frac rates up to 80 bbl/min (12.7 m3/min)

- Sleeve make-up length is 40 in (101.6 cm) or less

- Allows frac-port spacing as close as 15 ft (4.6 m)

- Compact and easy to handle

- No pup joints required for API

- No pup joints needed for standard BTC or LTC thread types

- Sleeves can be torqued through

- Sleeves can be installed in any order

- Proven for stage-by-stage wellbore management

- Optional Shift-Frac-Close® sequence stops flowback after stimulation

- Operated by the Innovus™ frac-isolation assembly

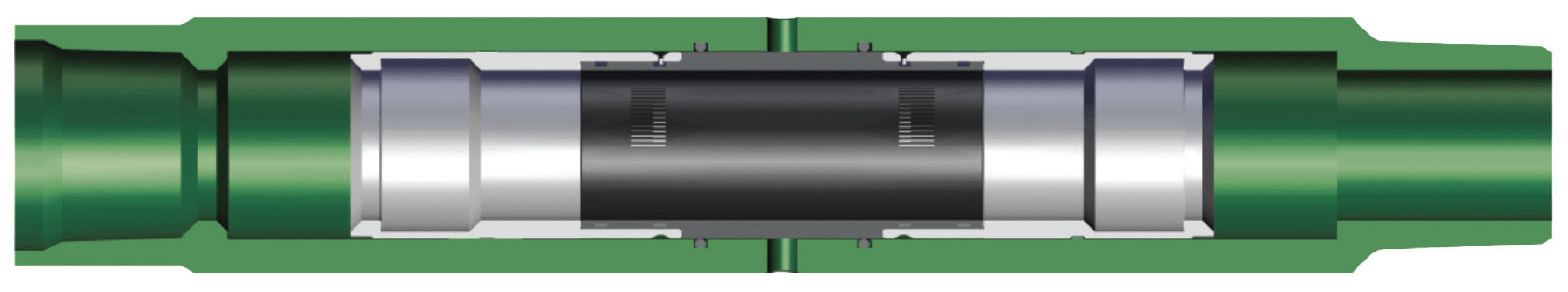

Terrus™ Injection Control Systems

The Terrus™ Injection Control System provides retrofit wellbore segmentation for regulated water-injection using the ultra-durable Torius™ Regulators.

Unlike bullheading or conventional injection-control-devices (ICDs), Terrus systems have options that allow individual zone injection to be adjusted post installation, individual zone shut off, and pressure-activated valves to eliminate the cost of initial intervention.

Further, the field proven Torius Regulator resolves the plug-off, washout, erosion and corrosion deficiencies that limit the performance and useful life of alternate systems.

This enhanced functionality and long-term performance allows geothermal well operators to optimize geothermal heat extraction from injector / producer well pairs by regulating and optimizing flow. Helping to avoid “cold circuits” and inject evenly between injector and producer wells.

Features and Benefits:

- Provides retrofit wellbore segmentation and injection regulation

- Controlled injection distribution to prevent “cold circuits” and maximize heat extraction

- Mitigates plug-off, washout, erosion and corrosion

- Designed for long-term use cases

- Deployed on production tubing

- Reliable-release compartment isolation packers for system retrieval if required

Proppex™ Frac Sleeve

Proppex™ was designed to keep proppant and unconsolidated formation sand where it’s supposed to be, on the outside of your geothermal wellbore.

After installing your next-generation geothermal completion system, you have the ability to stimulate the formation through the wide open ports in “open” mode.

When it’s time for production, Proppex™ can be shifted into “screen” mode to prevent unwanted sand and debris from entering the casing.

Features and Benefits:

- Screen size is customizable

- Compatible with cemented or open-hole completion strings.

- Normal pinpoint fracture operations can be performed

- Post frac, the FIA shifts into screen mode to prevent flowback

Tracer Diagnostics and Data Modeling

Tracer Diagnostics (TD) help our customers make better wells by verifying and measuring zonal contribution along the wellbore and evaluate connectivity and complexity between well pairs and / or offset wells. This information and data analysis helps identify key reservoir features and provides invaluable insight when making important development decisions.

In geothermal operations, especially in applications where similar stimulations from oil and gas are applied, tracer diagnostics offers:

- Simulation fluid recovery analysis

- Wellbore flow assurance via FFI liquid tracer deployment

- Produced oil & water analysis

- Better understand stage to stage production data

- Understanding connectivity and wellbore flow patterns via WST & OST

- Understand stage to stage stimulation effectives

- Evaluate fracture geometry with RA / Logging

- Understand where radioactive beads are placed in fractures

Data Modeling and Visualization

The FirstView™ application provides interactive, animated, 3D visualization of chemical tracer recovery and well-to-well fluid communication.

- A visualization platform targeted at data consolidation

- Displays stage numbers, tracer concentrations, and other information

- Allows uploading of RA logs as well as frac summary information

- Enables you to clearly see what is happening in your frac formations

Sample Analysis and Reporting

- Reporting for all projects is done using TIBCO Spotfire® software

- Reports are updated on a regular basis by a team of engineers

- Interpretation summaries provided with each data update

- Uses high-resolution liquid or gas chromatography-mass spectrometry

- Detects presence of tracers at concentrations as low as parts-per-trillion

- Processes include additional samples to ensure quality control of data

- Can integrate customer supplied data sets to enhance visual data

View the Tracer Diagnostics page for more information on our wellsite diagnostics services.