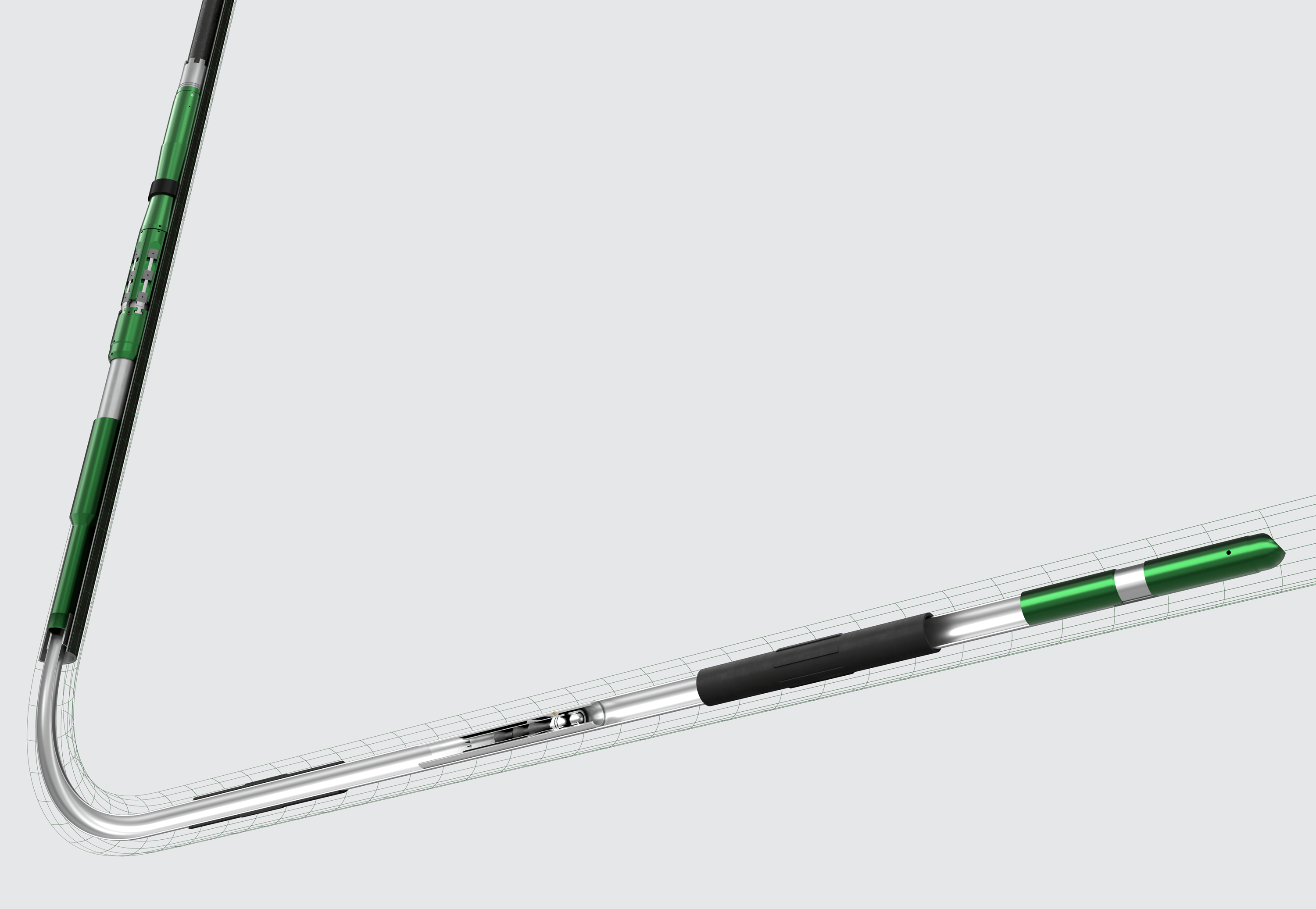

SlimStim™ Refrac System

Refrac Hanger Systems

Introducing the most rugged and refined mechanical isolation technology on the market. The SlimStim™ Refrac System handles high frac pressures while reducing stress on aging production casing.

The SlimStim™ Refrac System is more than a refrac liner hanger kit. It’s a fully featured system designed to meet the challenges of refracturing wells in unstable environments where sand, proppant, temperature, and other geological factors are present. Traditional technologies lack a reliable liner top packer and procedures for annular isolation and frac pressure containment. SlimStim™ Refrac Liner Hanger has been designed to reduce operational risk and maximize extraction.

SlimStim™ Features:

- Withstand pressures up to 12,000 psi without overlapping cement integrity.

- Enhanced hanging capacity, allowing for versatile placement throughout the wellbore while protecting the host casing.

- Get immediate first stage pump down and improve frac plug performance.

- Minimize disruptions with strategic contingencies.

- Reduce downtime and seal unplanned casing leaks.

- Run the liner to surface, restore host casing integrity, and establish isolation during refrac operations.

- Enhance wiping capacity for efficient plug and perf operations.

Each refrac hanger system’s design is dependent on your well’s specifications. We work with you to customize a refrac strategy to achieve your recovery goals and maximize extraction to ensure your SlimStim™ Refrac Liner Hanger delivers the results you’re looking for.

VectraSet™ Refrac Kit

3.5” x 7” Refrac Kit

The VectraSet™ Refrac Kit is made for wells with an original 4.5” x 7” production liner hanger installed. This kit bolt-on solution is not tied back to surface for permanent production and is designed to attach below VectraSet™ liner hanger systems. The 3.5” flush joint casing extends through the original liner hanger and existing 4.5” production casing to bottom. Cement in place, and it’s ready to go.

VectraSet™ Features:

- Protect casing integrity and avoid presets during RIH with recessed slips.

- Slim, short, compact design.

- Assembly guides the 3.5” casing string into the previous 4.5” casing string.

- Reduce friction and improve casing standoff, made for smooth re-entry into existing wells.

- Reduce costs by eliminating TCP runs.

- Prevent wellbore fluid and pressure from entering the casing string during installation.